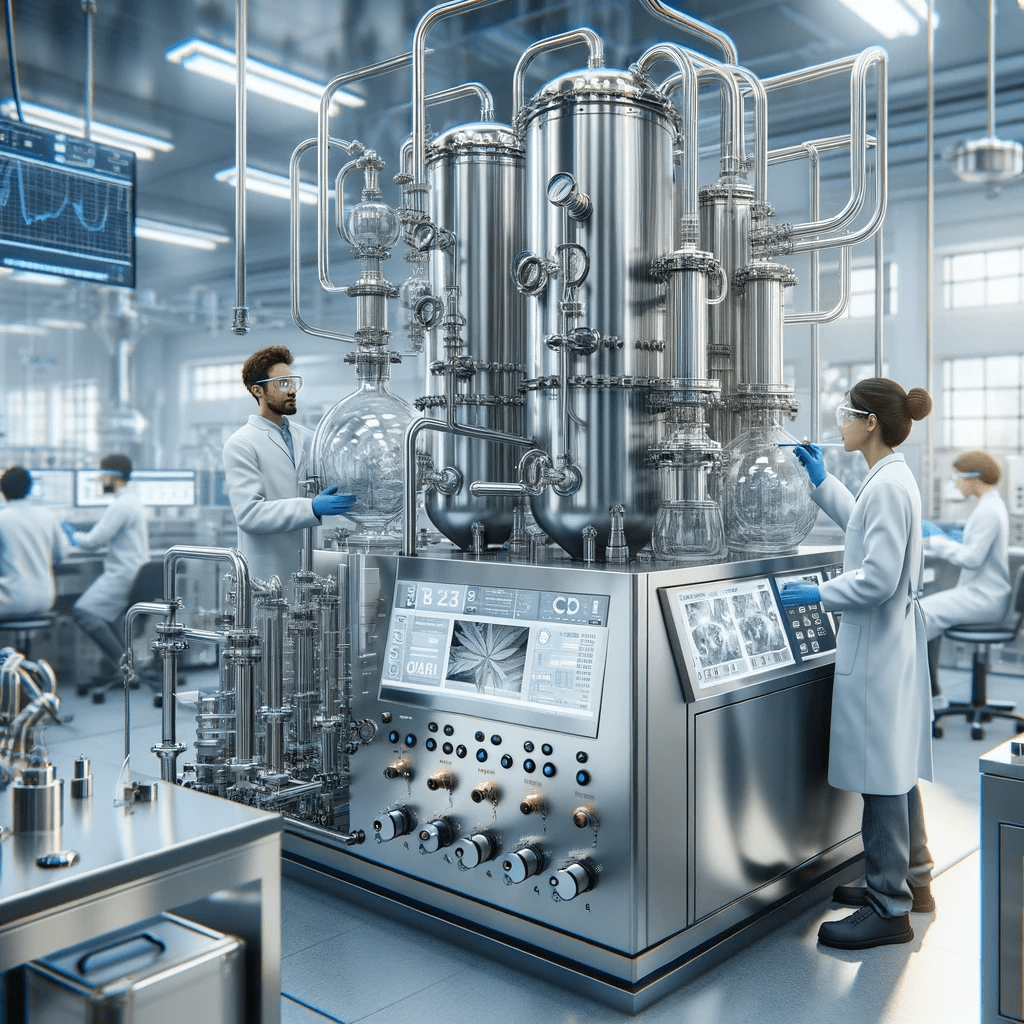

Latest Technologies That Are Revolutionizing the CBD Extraction Process. As the demand for CBD products continues to grow, it is essential to be knowledgeable of the best extractive methods to produce high-quality CBD.

Key Takeaways:

Advanced CBD extraction technology enables the production of cannabinoids with higher purity and potency, which is what consumers are looking for in their products.

New extraction methods are not only more efficient and cheap for botanical extraction companies, but provide for a wider range of new products available for sale.

It makes CBD extraction technology safe for the consumers and the environment, using developed instead of the makeshift basement and kitchen laboratories not only recreational use.

Solvent Extraction

- Preparation: Begin by grinding the plant material to increase its surface area for extraction.

- Extraction: Utilize a solvent such as ethanol to dissolve the cannabinoids and terpenes from the plant material, creating a sticky substance.

- Evaporation: Eliminate the solvent through evaporation, leaving behind the concentrated cannabinoids and terpenes.

- Purification: Further refine the concentrate to eliminate any impurities and unwanted compounds.

- Final product: The resulting concentrate is now ready for sale as a high-quality CBD extract, avoiding the dangers associated with illicit laboratories.

CO2 Extraction

- Preparation: The first step involves preparing the cannabis plant material by grinding it into small particles.

- Extraction: The ground material is placed into an extraction vessel, where pressurized CO2 is used to extract the cannabinoids and terpenes.

- Separation: After extraction, the CO2 and extracted compounds are separated, leaving behind a concentrated extract.

- Purification: The extract undergoes further purification to remove any residual solvents or impurities, resulting in a high-purity CBD extract.

When considering CO2 extraction, it’s essential to prioritize advanced CBD extraction technology for the strongest high and diverse cannabinoid profiles. This method is well-suited for both medicinal and recreational consumption.

Steam Distillation

The CBD extraction process also involves the use of steam distillation, one of the oldest methods of extracting essential oils from plants, especially hemp. It requires indirect process such as steaming the oil of plant in such a manner that the resulting steam and oil combination can be distinct and condensed. This gentle method doesn’t require any harsh solvents and, thus, can be used to obtain superior quality CBD products for medicinal as well as discretionary markets.

The quality of the hemp source and the expertise of the extraction process are important elements to consider when using steam distillation for CBD extraction. In addition to that, it is important to follow the legal protocols, particularly when creating CBD products for the purpose of recreational marijuana.

Hydrocarbon Extraction

- Extraction Process: In the early part of this century, hydrocarbon extraction methods gained popularity for their efficiency in extracting cannabinoids from hemp and marijuana plants.

- Stronger THC: This method allows for the extraction of stronger tetrahydrocannabinol (THC), resulting in products with a higher percentage content of this psychoactive compound.

- Purification: After extraction, the resulting extract undergoes a purification process to remove any residual solvents, ensuring the final product is safe for consumption.

Lipid Extraction

- Harvest mature cannabis plants with a balanced ratio of THC and CBD, typically between 15% to 23% THC.

- Dry the harvested plants to an optimal moisture content for lipid extraction.

- Grind the dried cannabis into a fine powder to increase the surface area for lipid extraction.

- Decarboxylate the ground cannabis to activate the cannabinoids for recreational consumption.

- Infuse the decarboxylated cannabis with lipids such as coconut oil or butter at controlled temperatures to extract cannabinoids effectively.

Higher Purity and Potency

For better extracts, which provide higher purity and potency for CBD products, focus on preliminary separation methods and individual cannabinoids.

Extraction methods: You should go for botanical extraction companies that apply modern extraction technologies such as CO2 or ethanol extraction for great purity.

Specific cannabinoids: For a high potency and targeted effects, consider products with specific cannabinoids such as CBD isolate.

Pro-tip: Extract CO2 First for Purest, Potent CBD Products.

More Efficient and Cost-Effective

To-date, extraction of CBD has advanced in terms of technology within the same line of improving efficiency and cost reductions to the new extracted products and the advanced methods spelled out in table I to IV.

Ingredients Safer for Consumers and the Environment

Technologies for extracting CBD have evolved to satisfy the consumers’ need for safe and eco-friendly products. It replaces the temporary basements and kitchen labs with formal regulated facilities that guarantee the consumers and the environment of their safety.

FAQs about Latest Advances In CBD Extraction Technology

What is the latest extraction technology being used in the cannabis industry?

The current generation the cannabis industry is using CO 2 processing equipment, the most costly, and newer-generation equipment brought in by chemical engineers who have had exposure to other botanical extractions.

How has the demand for stronger cannabis products impacted extraction technology?

The demand for stronger cannabis products, particularly those with high levels of THC, has led to a surge in the development of new extraction technologies that can produce more potent concentrates with consistent quality.

What are some of the new extraction products and techniques being used in the cannabis industry?

New extraction products and techniques being used in the cannabis industry include diamonds and sugars, which are essentially recrystallizations of cannabinoids, as well as newer methods utilizing CO 2, butane, and ethanol.

How are extraction experts and equipment manufacturers contributing to the development of new extraction technologies?

Extraction experts and equipment manufacturers are working together to bring new technologies to the cannabis industry, utilizing their knowledge and experience in other botanical extractions to create more efficient and effective processes.

What is the best approach to developing an extraction process in the cannabis industry?

The best approach to developing an extraction process in the cannabis industry is to start with the end product in mind and work backwards, determining the most suitable extraction method and chemovar (plant strain) to achieve the desired results.

What is the future outlook for extraction technology in the cannabis industry?

The future of extraction technology in the cannabis industry looks promising, with continued advancements and innovations being made to meet the growing demand for high-quality and consistent cannabis products.